【Type selection guide】Selection guide for single-head electric heating tube

A few words I want to say before the selection guide for single-head electric heating tubes:

★ Single-head electric heating tubes are generally non-standard customized, and are selected according to specific actual working conditions

★ The diameter of the single-head heating tube is less than 6mm, the thinner the more expensive

★ The length of the single-head electric heating tube is shorter than 50mm, the shorter the more expensive

★ The higher the surface load of the single-head electric heating tube, the more expensive it is

★ The price of the inner wire of the single-head electric heating tube is much higher than that of the outer wire

★The quotation of the single-head electric heating tube is not quoted by the meter, but needs to be quoted by integrating all parameters

What scenarios are single-head electric heating tubes commonly used in:

▲ In terms of installation mode, it is mainly used in two scenarios: embedded mold hole heating and exposed air dry heating

▲ Which devices are specifically used for:Plastic mold industry,Packaging sealing equipment,Pharmaceutical molding equipment,3D hot bending machine equipment,3D printer equipment,Extrusion equipment,Ignition equipment, etc.

☑ Selection guide for single-head electric heating tube——structure selection

CHC model,CHCC model,CHS model,CHSC model

Note: CHC model refers to: external wiring structure;CHCC model refers to: external wire + ceramic head structure;CHS model refers to: inner lead structure;CHSC model refers to: inner lead + ceramic head structure

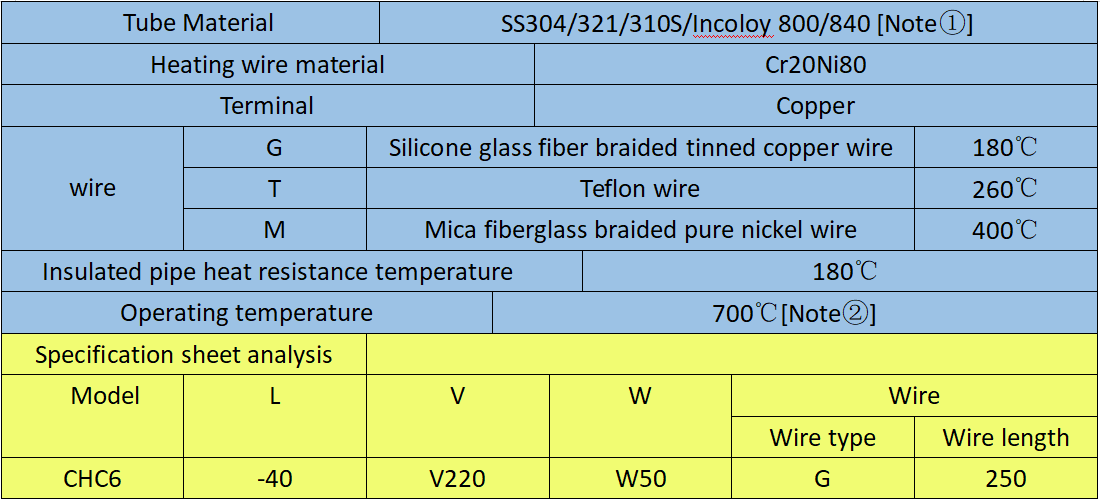

☑Single-head electric heating tube selection guide – technical parameter selection

Note ①: Suggestion for material selection: Surface load ≤ 6W/ cm2- SS304;6W/cm2<surface load≤12W/cm2 – SS321 or SS310S;12W/cm2<surface load≤20W/cm2 – SS310S or Incoloy 800/840

Note ②: The operating temperature is 700°C, which means based on the use of material SS310S or Incoloy800/840.This temperature is used for 1-year warranty in the embedded dry-burning environment, and 3-month warranty in the exposed air dry-burning environment.

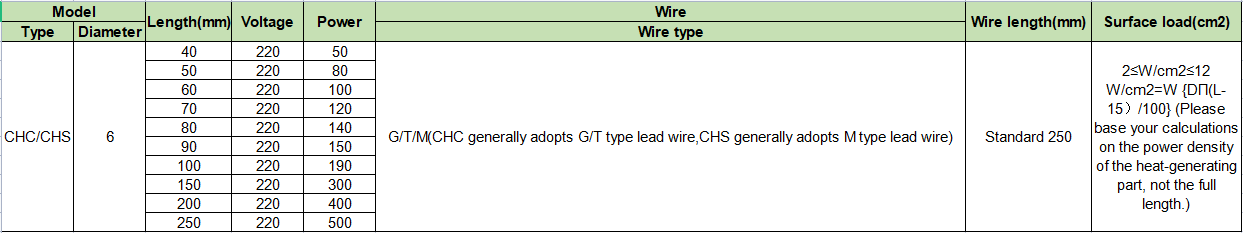

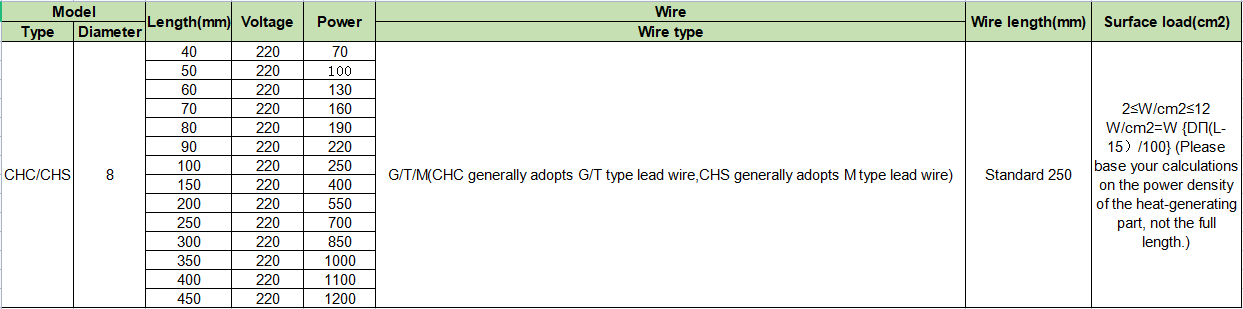

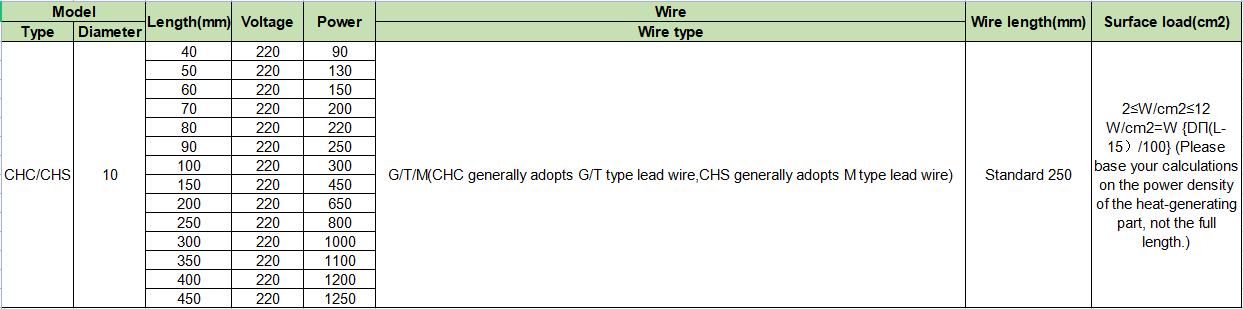

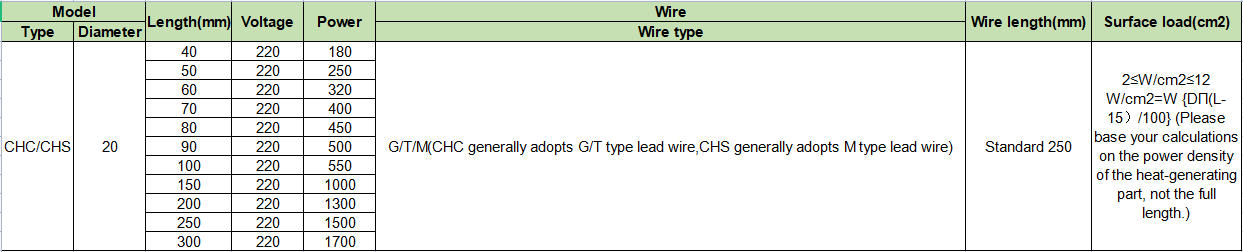

☑Single head electric heating tube selection guide——common size

※ 6mm pipe diameter common size

※ 8mm pipe diameter common size

※ 10mm pipe diameter common size

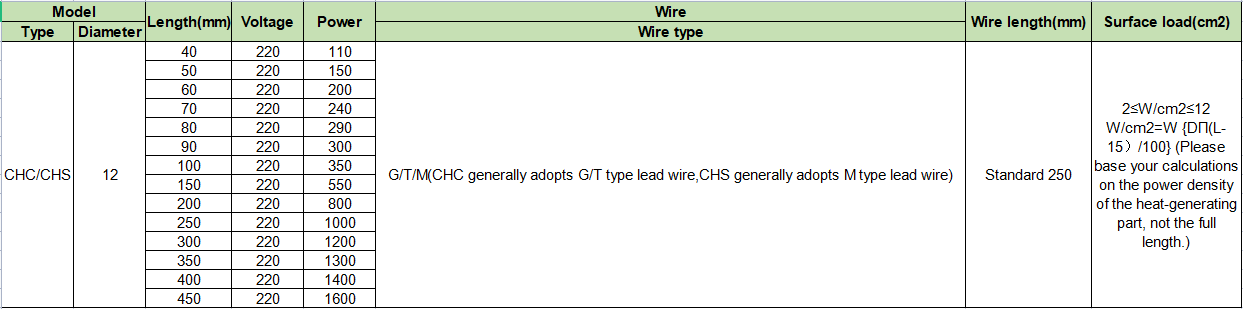

※ 12mm pipe diameter common size

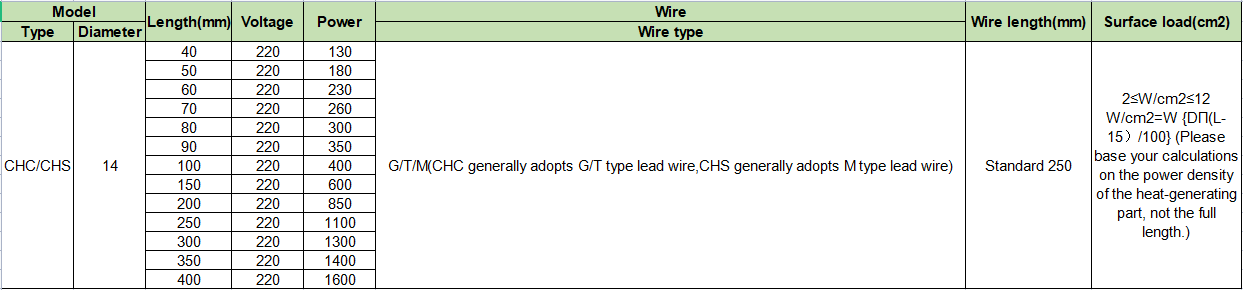

※ 14mm pipe diameter common size

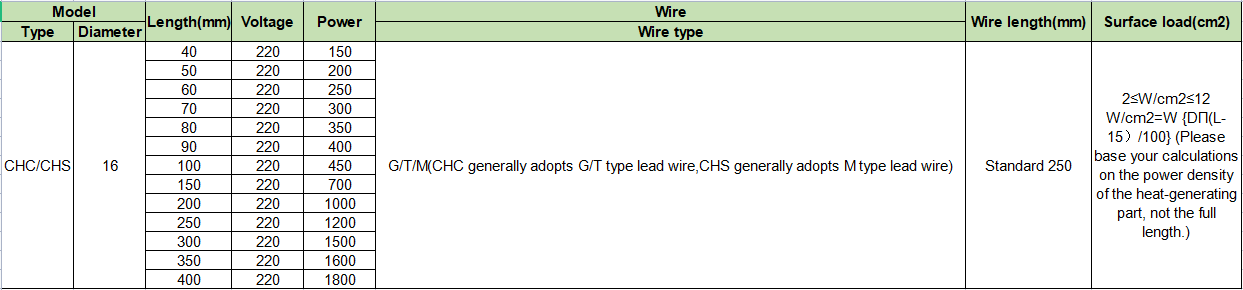

※ 16mm pipe diameter common size

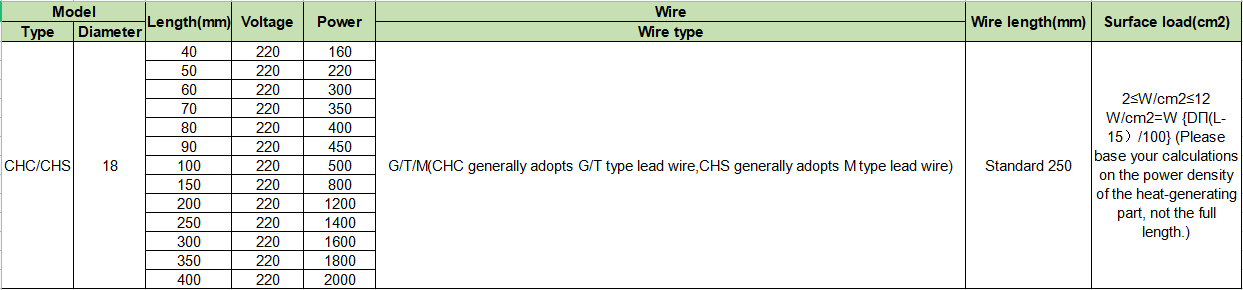

※ 18mm pipe diameter common size

※ 20mm pipe diameter common size

☑Guidance for selection of single-head electric heating tube——selection of other accessories

★Accessory 1 choice: thread

①The single-head electric heating tube with thread is generally used in the working environment of heating liquid.

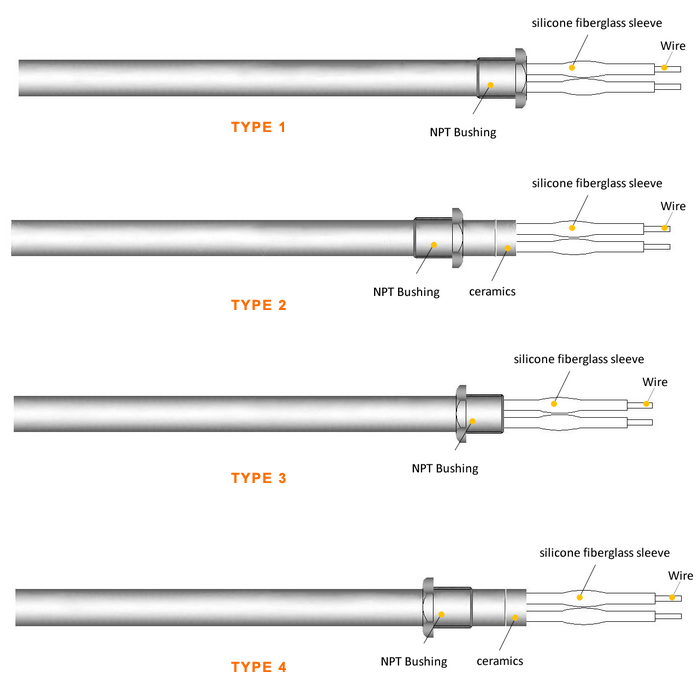

②Thread style selection: fastener thread (M), G thread, R thread, NPT thread, etc., can be equipped with nuts.

③Selection of thread position: refer to the style chart

④ Selection of thread material: According to the corrosion performance of the heating liquid, stainless steel 201, 304, 316, etc. are generally used

★Accessory 2 option: fixed bracket/flange

① The size and style of the fixed bracket/flange are not customized, and customers can also be consulted for help in designing.

②Selection of fixed baffle/flange material: According to the corrosion performance of the heating liquid, stainless steel 201, 304, 316, etc. are generally used.

★Three choices of accessories: wire protection method

① Lead protection method 1: metal hose sheath tube

②Lead wire protection method 2: metal braided sheath tube

★Four options for accessories: temperature measuring thermocouple

① General style of thermocouple: K/J type thermocouple

② Placement of thermocouples: grounded at the bottom of the tube, ungrounded at the bottom of the tube, grounded in the middle of the tube, and ungrounded in the middle of the tube.

☑Single-head electric heating tube selection guide——points for attention

▲ The working voltage must be consistent with the rated voltage, and the general working voltage should not exceed 10% of the rated voltage;

▲ To ensure that the heat generated by a single head electric heating tube can be transferred to the heating medium in a timely manner, and to reduce the temperature of the internal materials of the single head electric heating tube, during embedded heating, the gap between the outer diameter of the heating tube and its inserted hole diameter should be minimized as much as possible. Usually, the gap between the two is less than 0.1mm. For example, for an electric heating rod with a pipe diameter of 10mm, the hole should be within 10.1; When dry burning in exposed air, it is necessary to have surface temperature control, otherwise the lifespan will be short;

▲ When embedded heating, when machining the mounting hole, its coaxiality and size tolerance should be effectively guaranteed. If the machining hole is trimmed with tools such as reamers;

▲ Before installing the heating rod, the residue left in the process should be cleaned, such as organic oil residues, which will be carbonized after heating, thus affecting the ability of heat conduction;

☑Single-head electric heating tube selection guide——we help you design

【Selection guide】Selection guide for dry-fired electric heating tube

☑ Guidance for the selection of liquid electric heating tubes——design prerequisites

Before designing a liquid electric heating tube, we must understand a few things:

① The heated liquid, whether it is heated water, oil or corrosive liquid, etc.

②The pressure that the liquid electric heating tube needs to withstand after it is installed in the equipment

③Installation method: horizontal installation or vertical installation

④Installation space size

⑤The material of the installation container

☑ Guidance for selection of liquid electric heating tube – material selection

The material selection of the sheath of the liquid electric heating tube is mainly determined according to the condition of the heating liquid. Generally, it can be selected according to the following materials:

▲The case of heating water

| material | apply to |

| stainless steel 304 | non-corrosive, softened water |

| Stainless steel 316L | heating drinking water |

| Stainless steel 304+ anti-fouling coating | When the water quality is relatively hard, our anti-scaling coating process is mainly divided into: liquid coating and electrostatic powder coating |

| Stainless Steel 310S/Incoloy | High-end products, anti-scaling and anti-corrosion |

▲In case of heating oil

| material | apply to |

| carbon steel | General heat transfer oil, lubricating oil, etc. |

| stainless steel 304 | General heat transfer oil, lubricating oil, etc. |

| Stainless steel 304+ anti-fouling coating | General oil is not very good heat transfer oil, lubricating oil, etc. |

☑ Guidance for selection of liquid electric heating tube——selection of heating tube style

Generally, the style of liquid electric heating tube is selected according to the power. Common styles:

※Threaded single-head electric heating tube

※U-shaped or special-shaped (according to customer requirements)

※Hexagonal threaded electric heating tube

※Threaded electric heating tube with adjustable temperature control

※Plane flange electric heating tube

☑ Guidance for selection of liquid electric heating tube – power design

Without considering the heat loss, it can be calculated by the following formula:

The calculation formula is: required power (kw) = weight of water (kg) * temperature difference * specific heat capacity of water {kJ/(kg °C)}/time (seconds)

for example:

For example, if the initial temperature is 10°C, what is the power of the electric heating tube required to heat 500kg of water to 90°C in 60mins (3600s)?

The calculation formula is: required power (kw) = weight of water (kg) * temperature difference * specific heat capacity of water {kJ/(kg °C)}/time (seconds)

Substituting the formula to calculate the total power = 500*(90-10)*4.17/3600=46.33kw

Considering heat loss, the general design power is higher than the power calculated by the formula.

☑ Guidance for selection of liquid electric heating tube——design of heating tube surface load

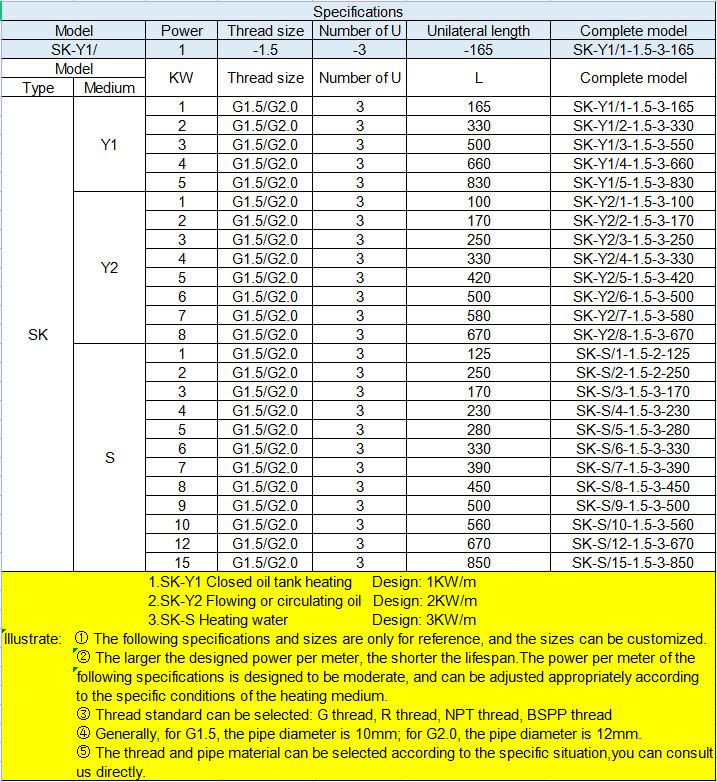

Core idea: The higher the surface load, the worse the life of the electric heating tube; therefore, a reasonable surface load design is the most important.【For the convenience of understanding, we simplify the surface load into power per meter.】

| heating medium | Recommended Power per Meter [Note ①] |

| Closed sump heating oil Y1 | 1KW/m |

| Flowing or circulating oil Y2 | 2KW/m |

| Tap water S1 | 2-3KW/m |

| Purified water S2 | 3-4KW/m |

Note ①: Here, each meter refers to the length of the heating area of the heating tube.The recommended power per meter is not guaranteed.

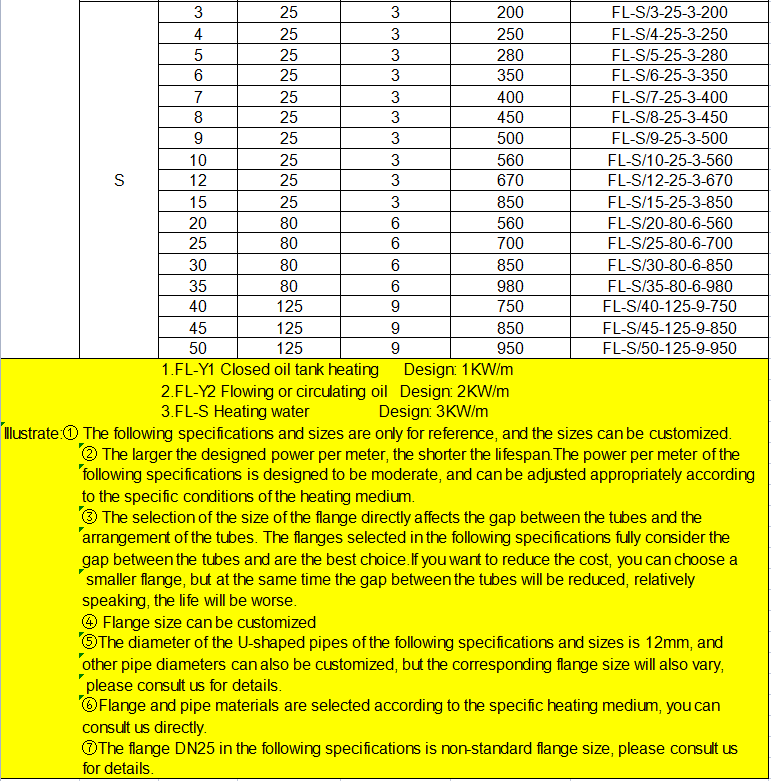

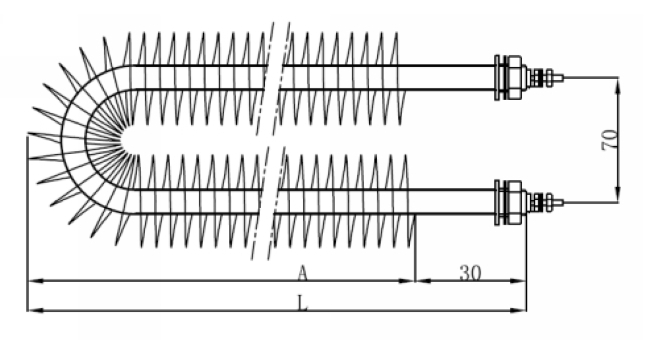

☑ Guidance for the selection of liquid electric heating tubes——common specifications and sizes of hexagonal threaded electric heating tubes

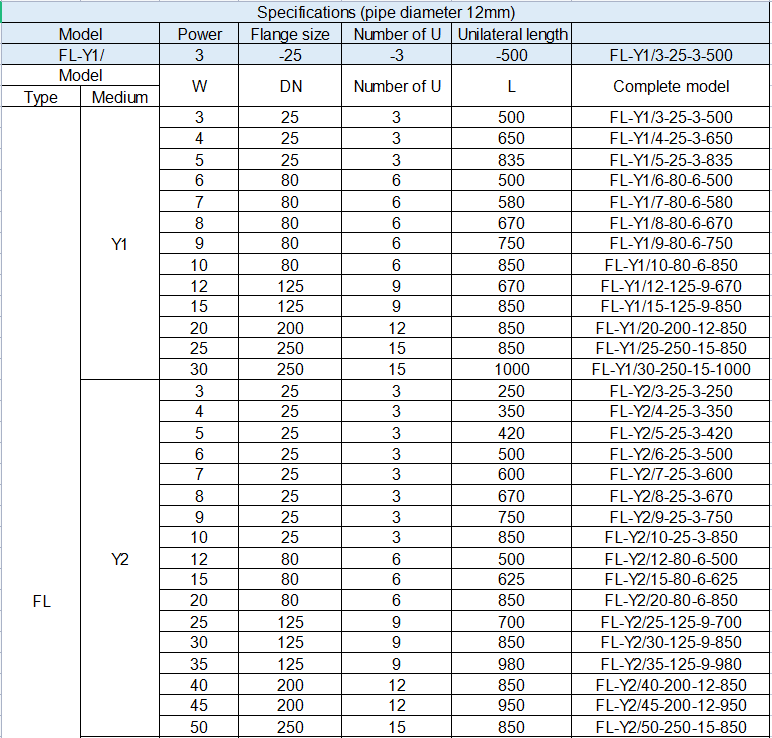

☑ Guidance for the selection of liquid electric heating tubes——table of common specifications and sizes of flat flange heating tubes

☑ Guidance for the selection of liquid electric heating tubes——points for attention

1. Do not use unstable containers. Before installing the electric heating tube, make sure that the container is placed stably, and then install and fix it.Because the unsteady container is easy to overturn and pour liquid, causing the electric heating tube to burn dry, because of its fire, electric shock and other risks

2. Do not use the electric heating tube in a heating container that is lacking in oil or contaminated with sediment. Heating the electric heating tube in oil with a high amount of impurities can easily cause damage to the electric heating tube due to surface carbon deposition and the inability to dissipate the heat generated in a timely manner (if the scaling is severe, coating can be used to treat the heating tube). At the same time, ensure that the heating liquid level is not lower than the normal liquid level standard, Otherwise, it may also cause damage to the heating pipe, fire, and other hazards

3. When the electric heating tube is heating the oil, it is necessary to ensure the size of the installation place. If the space is limited and the amount of oil is limited, the heat of the heating tube will not be released in time and may burn out.

☑ Selection Guide for Liquid Electric Heating Tube——We design for you

【Selection guide】Selection guide for dry-fired electric heating tube

☑ Dry-fired electric heating tube——design prerequisites

Before designing a dry-burning electric heating tube, we must understand a few things:

① Is the heating tube embedded dry-fired or dry-fired with exposed air?

②Whether there is wind circulation when the bare air is dry-fired?

③Working environment and working temperature

④Installation space size

☑ Selection guide for dry heating electric heating tube——material selection

The sheath material selection of the dry-burning electric heating tube is mainly determined by the surface load of the electric heating tube, and the surface load determines the surface of the electric heating tube. Generally, the following materials can be selected:

| Tube material | Recommended Surface Load | Heating medium |

| Stainless steel 304, 321, 316L | 5W/cm2 | still air |

| Stainless steel 304, 321, 316L | 5.5W/cm2 | the wind speed is not lower than 6m/s |

| Stainless steel 310S, Ingle 840, 800 | 10W/cm2 | still air |

| Stainless steel 310S, Ingle 840, 800 | 11W/cm2 | the wind speed is not lower than 6m/s |

☑ Guidance for selection of dry-burning electric heating tubes – selection of heating tube styles and size recommendations

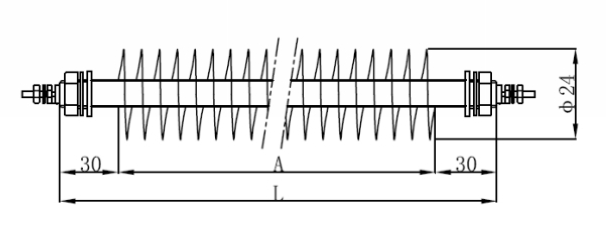

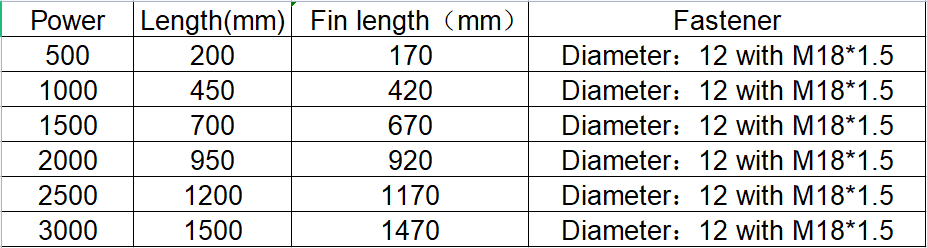

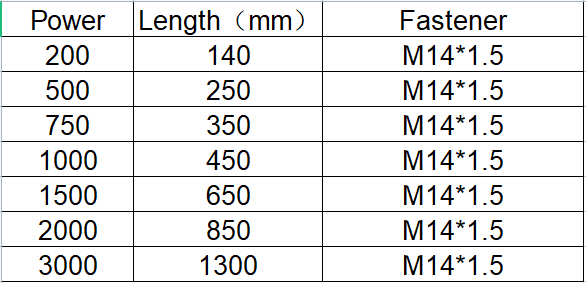

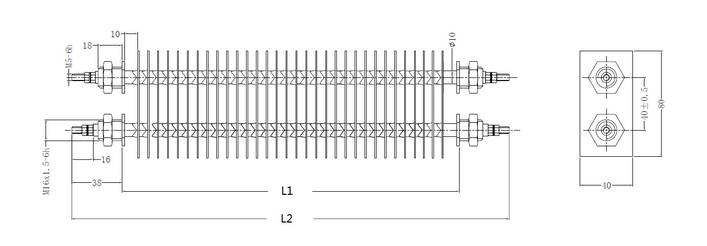

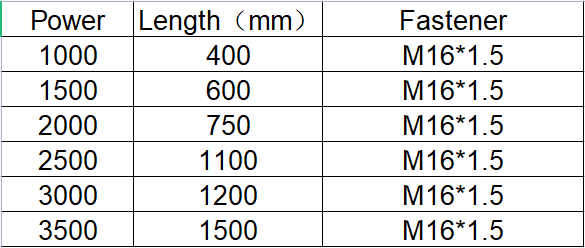

※ Wound Fin Straight Rod Type

(Power:W)

(Power:W)

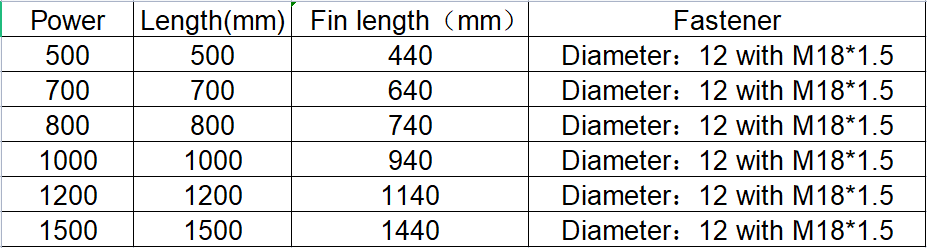

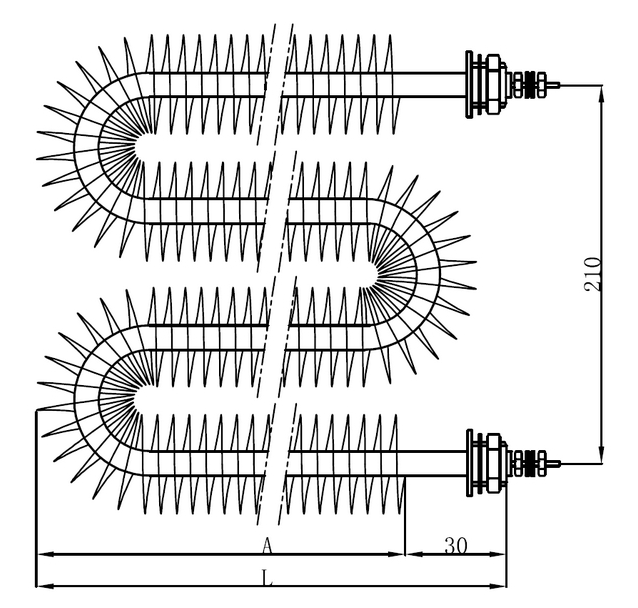

※ Wound fin U type

(Power:W)

(Power:W)

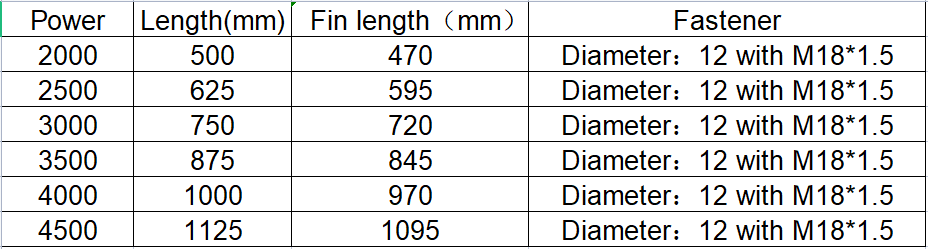

※ Wound fin W type

(Power:W)

(Power:W)

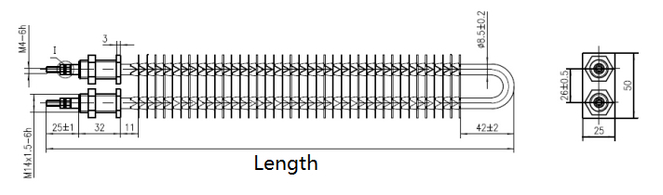

※ Square fin 25*50 type

(Power:W)

(Power:W)

※ Square fin 40*80 type – can be 2 straight rods, or U-shaped

(Power:W)

(Power:W)

☑ Guidance for selection of dry-burning electric heating tubes-points for attention

①The most important principle for the use of dry-burning electric heating tubes is that the heat dissipation is better, the air flow is better, or when it is embedded in the hole, the gap should be small.Only when the surface of the dry-burning electric heating tube dissipates heat well can the life of the heating tube be good.

②When the dry-burning electric heating tube is used, the rated voltage needs to be stable, and if the deviation is too large, the surface load of the dry-burning electric heating tube will increase, causing the surface temperature to be too high and overloaded.

☑ Dry heating electric heating tube——we help you design

【Type selection guide】 Selection guide for straight rod or special-shaped electric heating tube

☑ Straight rod or special-shaped electric heating tube——design prerequisites

Before designing straight rods or special-shaped electric heating tubes, we must understand a few things:

① The working environment of the heating tube, embedded dry burning? Dry burning in exposed air? Or heating the liquid?

②Selection of heating tube shape

③Consider how to install and the size of the installation space

④Contact sales staff to help you consider surface load design and material selection

☑ Guide for selection of straight rod or special-shaped electric heating tube——consider surface load and material selection

Core idea: the higher the surface load, the worse the life of the electric heating tube;Therefore, reasonable surface load design is the most important.【For the convenience of understanding, we simplify the surface load into power per meter.】

| Heating medium | Recommended Power per Meter [①] |

| Closed oil tank heating oil | 1KW/m |

| Flowing or circulating oil | 2KW/m |

| Tap water | 2-3KW/m |

| Pure water | 3-4KW/m |

| Dry burning without air circulation | 1KW/m |

| Dry burning with air circulation | 1.5KW/m |

(①: Each meter here refers to the length of the heating area of the heating tube.The recommended power per meter is not guaranteed.)

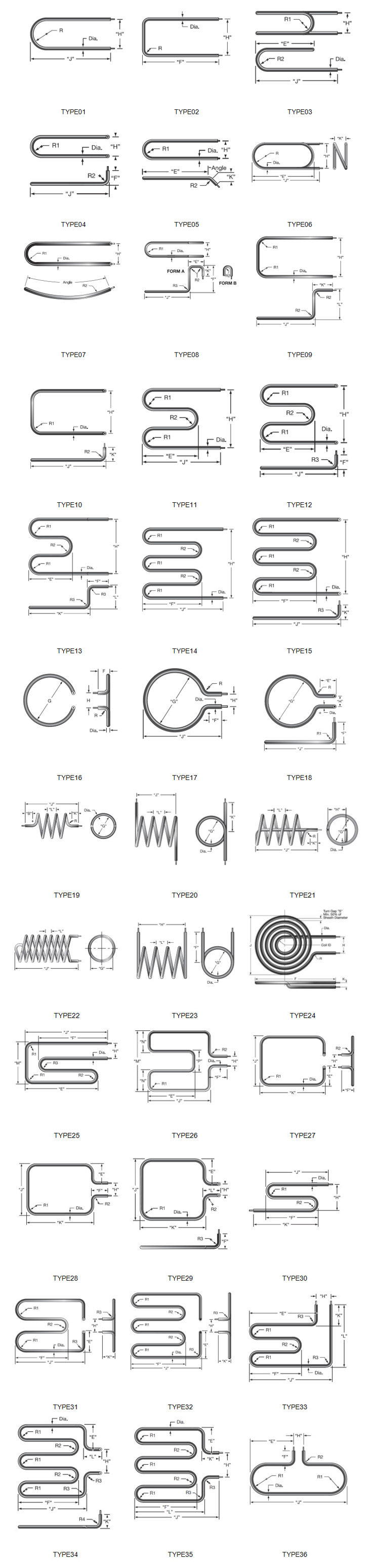

☑ Guide for selection of straight rod or special-shaped electric heating tube——shape selection

☑ Guide for selection of straight rod or special-shaped electric heating tube – we design for you